Diagnostics & Analytics Workflows with EICEbox

Automate well and equipment performance monitoring and analysis in real-time

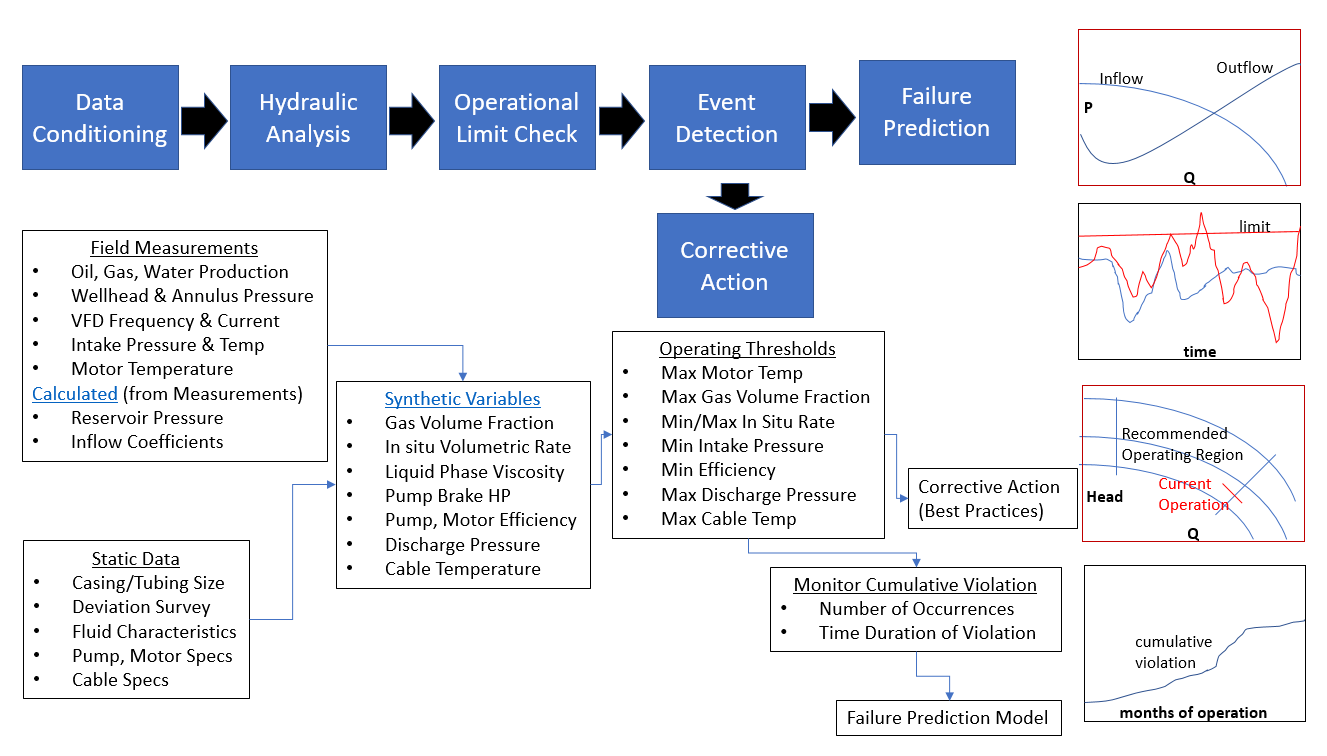

ESP Diagnostics

Well Performance Analysis from Shut-In

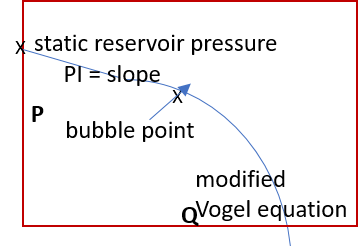

- Flowing Condition

- Intake Pressure at known production rate

- Characteristics of produced fluid (oil, gas, water gravity)

- Reservoir temperature, pressure (from shut-in) Approach

- Determine bubble point pressure from fluid characteristics and downhole temperature

- Adjust intake pressure for bottom-hole (sand face) conditions (liquid column)

- Determine best fit Productivity Index (PI) for inflow curve

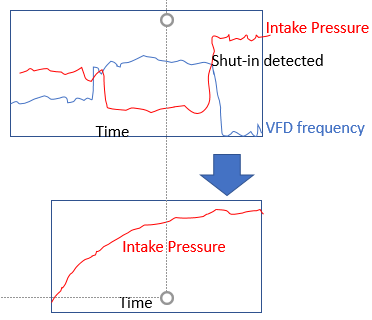

- Shut-In Condition

- VFD frequency (or other signal for shut-in detection)

- Intake pressure vs. time following shut-in Approach

- Detect shut-in

- Adjust intake pressure for bottom-hole conditions

- Create buildup plot (bottom-hole pressure vs. time)

- Determine permeability (kh), skin, static pressure from analysis of buildup

-

Data required

-

Data required

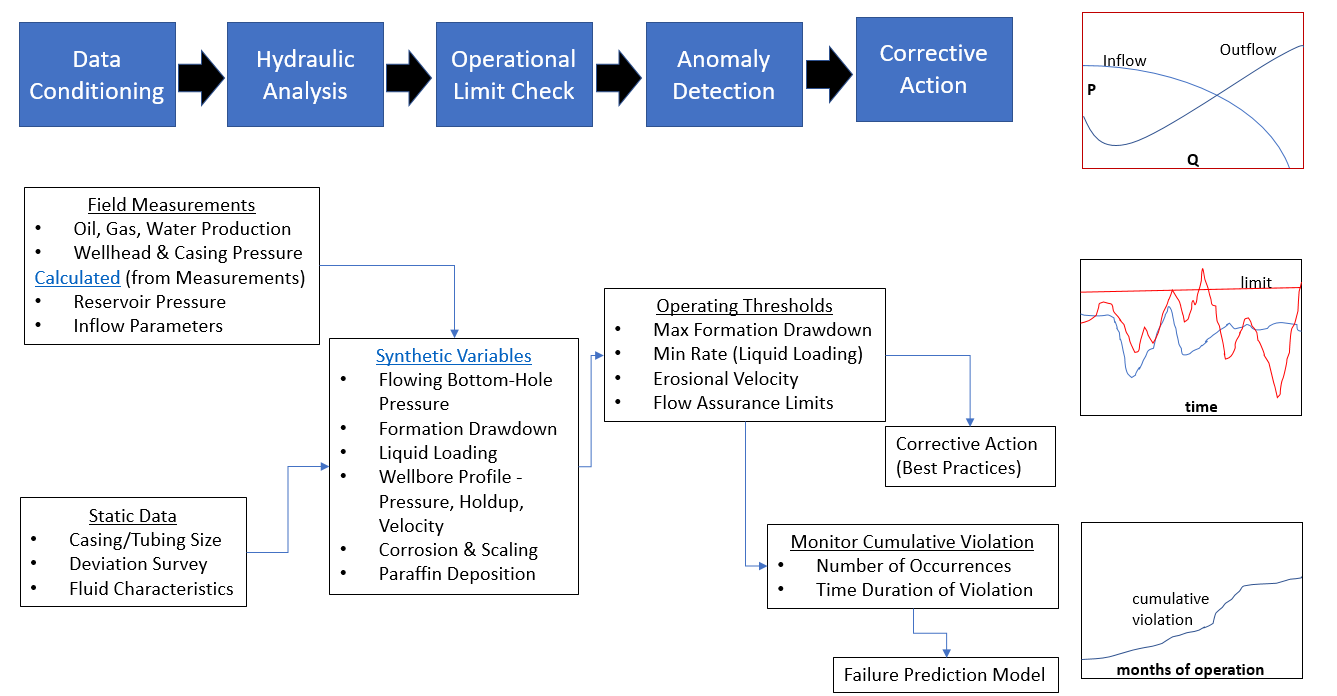

Gas Well Anomaly Detection

Virtual Metering

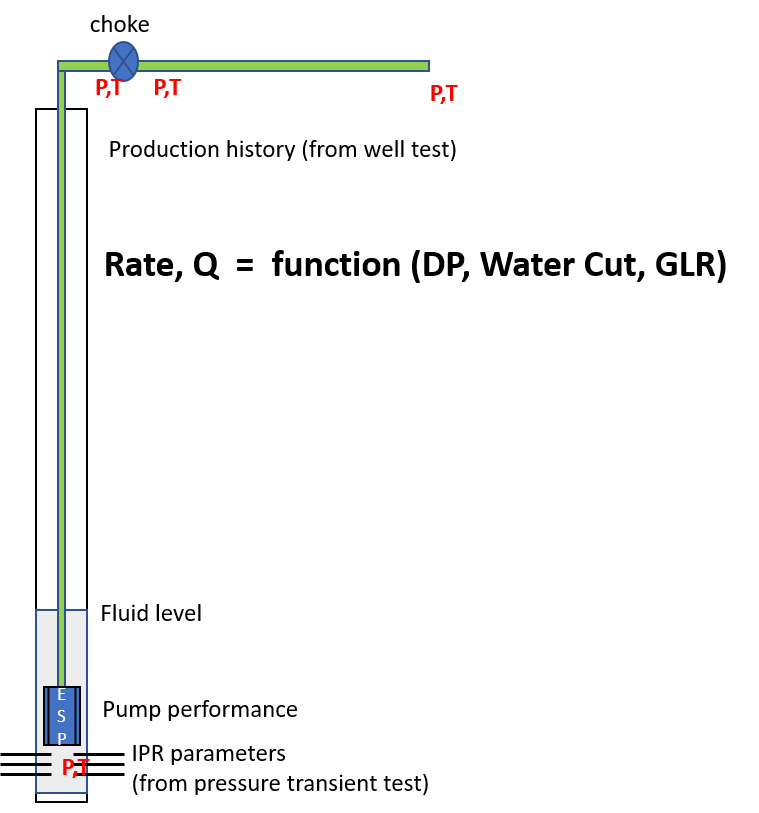

ObjectiveEstimate current oil, gas and water rates based on available measurements from SCADA, and leveraging supporting data from production history, reservoir inflow performance, etc. for additional validation

Data Sources- Pressure (and temperature) -bottom-hole, wellhead, and flowline (downstream of choke)

- Well operations - choke setting, frequency (ESP), injection rate (gas lift), SPM (rod pump), etc.

- Production test (and allocation) - historical production rates for oil, gas and water

- Pressure transient testing - static pressure, IPR parameters (e.g. skin, permeability, drainage)

- Fluid level (from surface pressure wave)

- Statistical analysis / numerical weighting of rate calcs from multiple INDEPENDENT estimates

- Well performance analysis from reservoir to wellhead/separator (intersection of IPR and VLP)

- Reservoir inflow analysis (with bottom-hole gauge)

- Choke pressure drop (subcritical flow)

- Choke temperature change

- Pump performance (ESP)

- Validation

- interpretation and interpolation of production history

- Comparison with other wells

- Aggregation of group production (at separator/plant)