Monitoring & Surveillance Workflows with EICEbox

Extend traditional SCADA-based surveillance with real-time model-driven monitoring

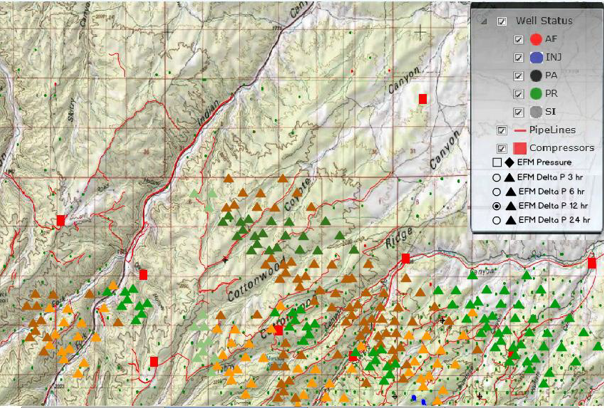

EICEbox for Field-Wide Operations Surveillance

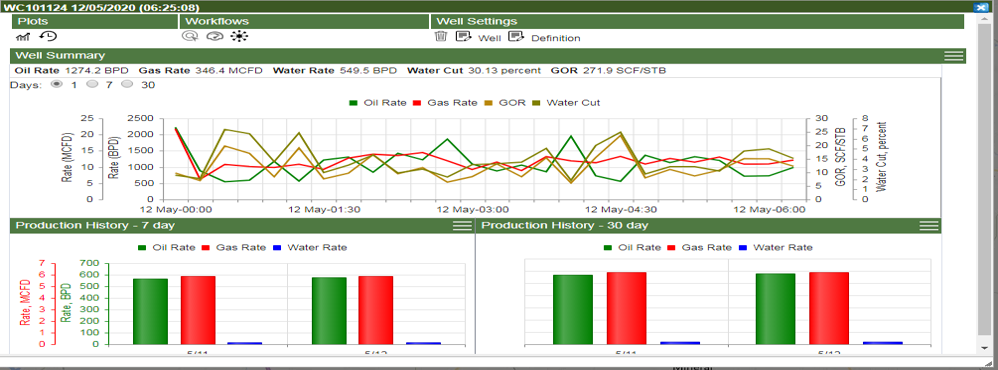

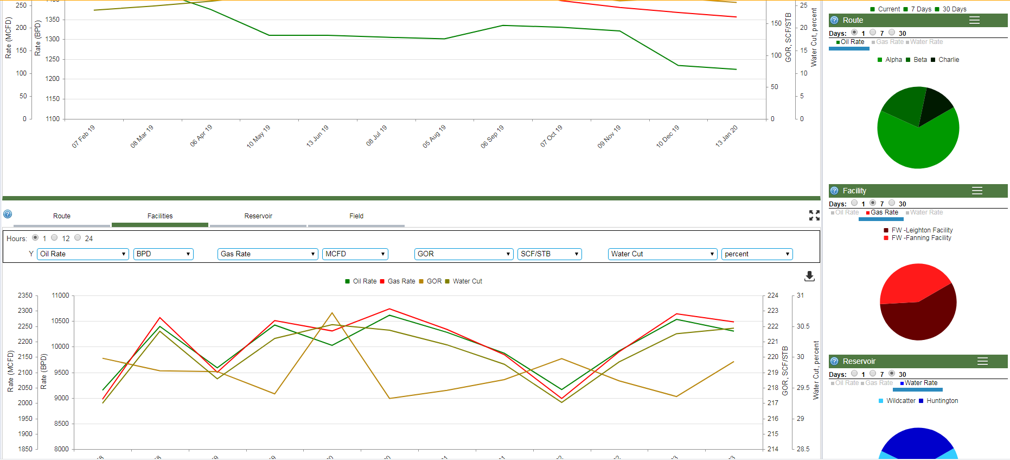

Visualize relevant well & equipment data context

- Graphical - plots, charts & tables

- Geographical - map view (GIS)

Group wells based on operational focus

- by Facilities (common separation)

- by Reservoir (common pool)

- by Route (common operator)

- Field (all wells)

Sort & filter assets based on operational priority

- by Well Type – production/injection/shut-in/abandoned

- by Artificial Lift method employed

- by Production - rate / water cut / GOR / history / ownership

- by Priority - current alarm notification(s) and history

Integrate disparate data source in one common context

- SCADA / DCS - surface/down-hole, equipment, tank, injection

- Production History – oil, gas, water, injection, GOR, water cut

- Engineering (static) – equipment/tank performance

- Synthetic - model-based (calculated)

Aggregate Production

- by Operating Period - daily, 7-day, 30-day, lifetime

- by Production & Volume - oil, gas, water, GOR, water cut

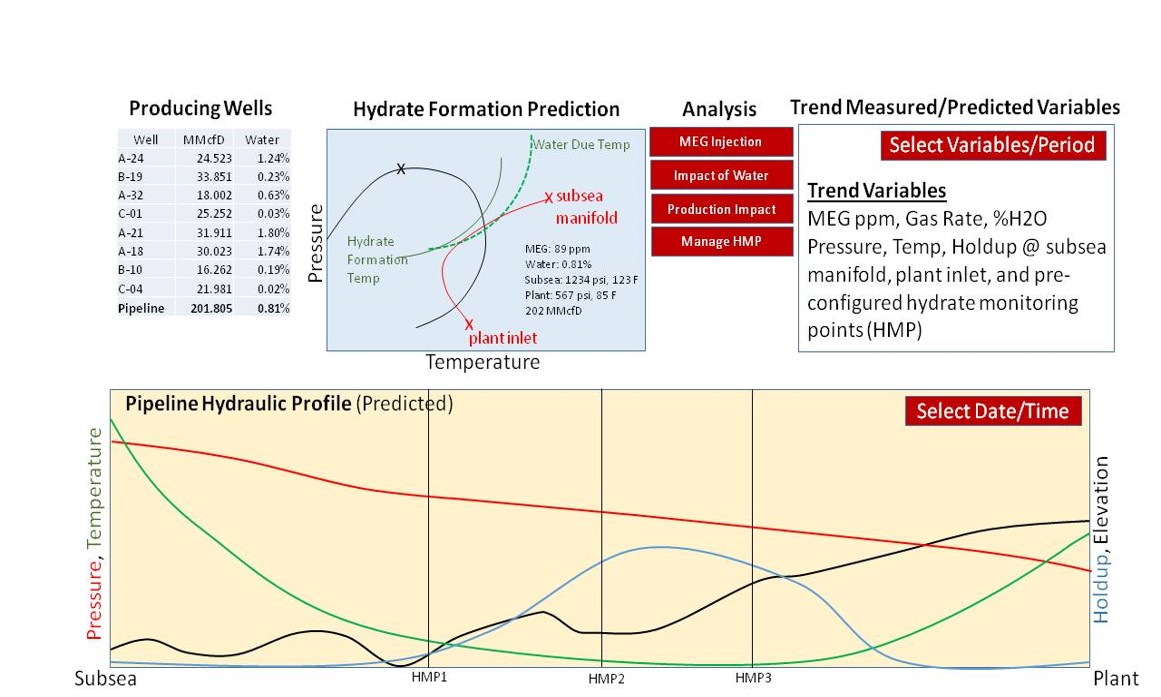

Hydrate Monitoring

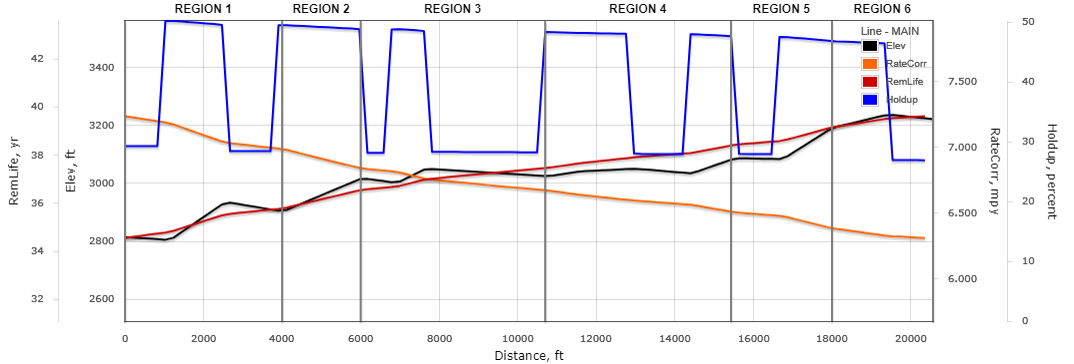

Real-time pipeline profile prediction for monitoring potential for hydrate formation and managing MEG inhibitor injection

Corrosion Monitoring

- Identify vulnerable sections of the pipeline with rigorous multiphase hydraulics integrated with corrosion analysis

- Use the ICDA methodology to segment pipe based on elevation profile, flow rate, fluid, contaminants, and physical pipe conditions

- Monitor corrosion rates and remaining life for corrosion-susceptible sections of the pipeline

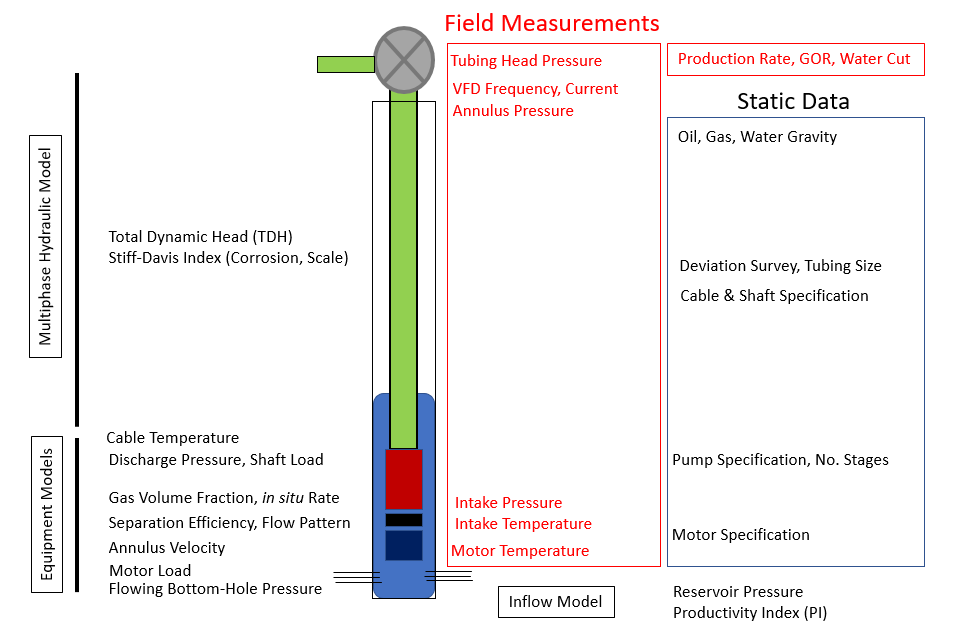

ESP Performance Monitoring

Algorithm Outline*

(executed every timestep)

- Estimate Production Rate

- Compute Flowing Bottom-Hole Pressure from Inflow Model

- Compute Pump Inlet Pressure (PIP)from an iterative forward marching algorithm

- Compare measured vs. calculated PIP; adjust production rate and iterate (steps 2-4) until convergence

- Estimate Gas-Oil Ratio (GOR)

- Calculate multiphase hydraulic profile in wellbore (segment-wise iterative reverse march) starting from measured Tubing Head Pressure

- Determine Total Dynamic Head (TDH)

- Calculate pump operating parameters from TDH

- Compare calculated pump intake pressure against measured; adjust GOR and iterate (steps 6-9) until convergence

- Calculate Motor and Cable parameters

*actual implementation approach will vary based on quality/frequency of measurements

Pressure Profile Monitoring

Leveraging pressure profile to track movement of flowline freezing front in winter conditions