Production Optimization Workflows with EICEbox

Drill down from diagnostic analysis to improve performance, extend run life, reduce down-time and lower lifting costs

ESP Optimization

- Surveillance

- Real-time measurements from SCADA

- Bottom-hole pressure, temperature, vibration

- Surface pressure, choke setting

- Frequency/speed, current, voltage

- Well Test / Production Allocation

- Liquid rate, GOR, water cut

- Surface fluid characteristics - oil, gas and water gravity

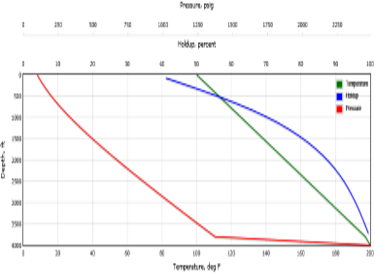

- Model computed values

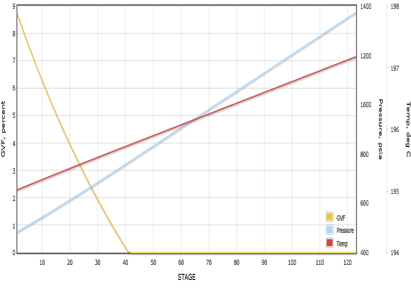

- Gas Volume Fraction (GVF) at pump intake

- Motor winding temperature

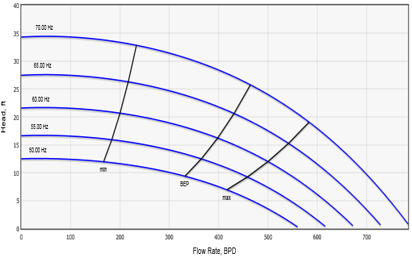

Display operating point on performance envelope, trends for measured/calculated operating parameters and generate alert notification when value outside operating envelope

- Diagnostics

- Examples

- Excessive gas at intake - adjust choke to lower production and increase flowing BHP

- Overheating motor - increase velocity past motor (shroud)

Enable operations engineer to drilldown via engineering analyses and identify the cause of surveillance alert notifications and proactively take remedial action

- Optimization

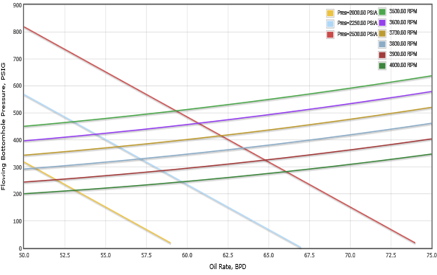

- Increase production - determine optimal speed through nodal analysis

- Extend pump life - maximize operation within the operating envelope

- Lower lifting cost

- operate within BEP region

- adjust operations so gas breakthrough in tubing occurs at a lower depth

- minimize choking

- debottleneck gathering system (network analysis)

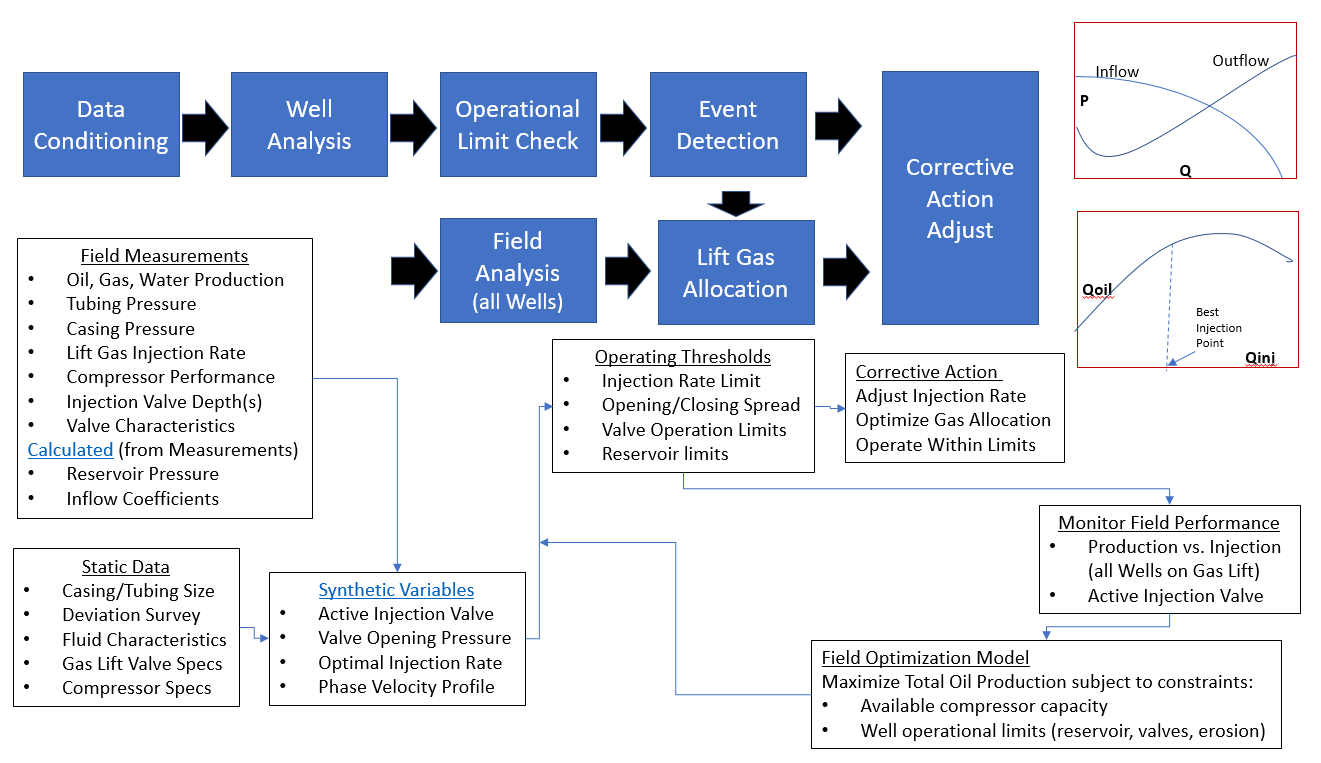

Gas Lift Optimization